In order to determine whether infrared heating elements will be effective for your process, feasibility testing is necessary. This testing must be performed with the correct configuration of the heater and product. If not, the results may be erroneously good.

Long wave heating

Electric infrared (IR) is a type of radiation. It travels in straight lines from the source of heat. Then, it diffuses, reducing in intensity with distance. This radiation can be used to heat objects. But, it is important to note that IR energy is not the same as visible light.

This type of radiation is not dangerous to the environment. Its intensity is not high enough to cause damage to DNA, and it is direct on the surface of the material being heated. Additionally, it produces no volatile organic compounds or nitrogen oxides. Furthermore, the process of heating does not require any kind of heat recycling or isolation system.

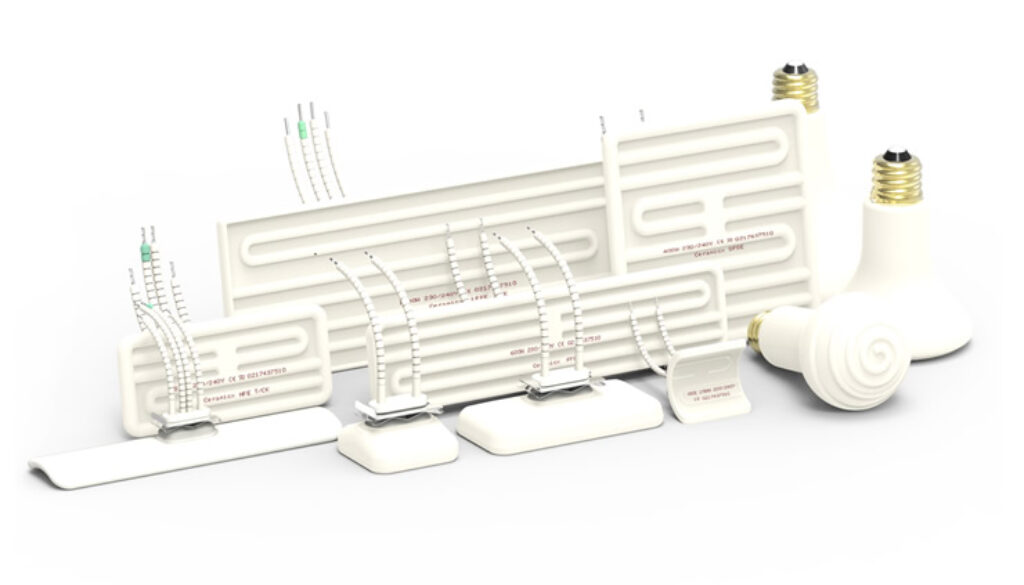

Infrared heating elements can be categorized into two types: long wave and medium wave. Long wave heating is used in applications where a slower heating rate is required. This type of heating element can produce heat up to 2000degF. But, the long wave is not widely used.

Ceramic infrared heating elements are typically used in industrial processes and animal/pet care. Their useful wavelength range ranges from 2 to 10 mm. They are also commonly used in emitter banks. The ceramic emitter emits uniform heat over a surface.

Electric infrared heating elements have another feature called staging control. This feature allows the heat source to only energize a part of the equipment. This means that only half of the capacity is used during the first stage. During the second stage, two heat sources in each fixture will be active, which makes large spaces uniformly comfortable.

Electric infrared heating systems can lower air temperatures compared to traditional heating systems. These systems create radiant energy that warms the surfaces of the room and occupants. They can also be used in a variety of conditions, such as hot or cold temperatures.

Infrared technology is highly energy efficient, water-saving, and environmentally friendly. It also has high heat transfer and low heating time, and is more efficient than other heating methods. In addition, infrared technology is smaller and offers accuracy.

Compact design

Using infrared heating elements can help you save energy and increase productivity. In addition, they can help you reduce floor space requirements and increase product quality. There are, however, some factors that you need to keep in mind before investing in infrared heating equipment.

Unlike other heaters, infrared heaters do not have fans or moving parts, which means they are quieter and safer to use in cold weather. Infrared heaters use a circular coil that evenly transfers heat. These heaters also use special polished metal that reflects the heat.

Infrared heating elements are highly effective at warming objects and people. They are also electrically powered, which means that they can react quickly to any changes in temperature. This makes the heating process easier and faster, and also results in more consistent output and product quality. Furthermore, infrared heating is versatile and easy to control.

Another important feature of infrared technology is that it is environmentally friendly. Unlike other heating methods, infrared technology is low in water and energy-efficient. They are also small in size and have unique radiative properties. As a result, they are considered a viable alternative energy source.

Before making a final decision to use infrared, it is essential to conduct feasibility tests to make sure the technology will work well for your process. Ensure you run tests with the correct heater and product configuration. Otherwise, the results may be wrong. Infrared heaters are an excellent choice for quiet environments.

Infrared heating panels also reduce energy costs and energy bills. As they directly heat objects, they do not lose heat through draughts. These panels can also help you transition away from gas. In addition, they are compatible with solar panels and renewable energy tariffs. However, there are some disadvantages of infrared heating. You should use infrared panels in conjunction with a water cylinder or electric immersion heater to achieve optimal heat output.

Besides being environmentally friendly, infrared heaters are also very effective at lowering air temperature. Unlike conventional heaters, infrared heating uses radiant energy to warm objects in the room and your body. This way, you can achieve your desired comfort levels in different zones of the building.

Energy efficiency

Electric infrared heating elements provide instant heat, with minimal maintenance. They do not have air filters, motors, or other moving parts that can wear out. All they require is periodic cleaning of the reflectors and replacement of the heat source. This type of heating element is also a good option for large areas where temperature control is key.

Infrared heating elements produce heat by radiating heat. The amount of radiant energy emitted depends on the wavelength of infrared energy, as well as the material and surface the heating element is placed on. As the source of heat changes in temperature, the wavelength of infrared radiation changes. For example, a 3600-degree-F heat source emits a short-wave of one mm, whereas a 1000-degree-F source produces a long-wave of 3.6mm. This difference in wave-length dramatically affects the intensity of the radiation at the subject.

Another important factor to consider when selecting an infrared heating element is energy efficiency. The cost of energy to run an infrared heater will vary depending on its size, type, and location. If you need a heating element for a small room, a smaller unit will not be as efficient as a large model.

Electric infrared heaters operate by using electricity to deliver heat. Electricity is converted to heat by passing an electric current through a high-resistance metal, such as tungsten. To get the most energy efficiency from an electrically heated object, the resistance of the heating element must be less than the resistance of insulators. Common heating element materials include tungsten, iron, and copper.

Electric infrared heating elements can provide heat to a variety of applications, including heating floors and walls. They can also be used to warm up water, which helps reduce the risk of flooding. However, infrared heating elements do not produce ultraviolet light, and therefore do not contribute to global warming. Hence, these heaters should be used carefully, in order to avoid any possible risks. If you are considering an infrared heating element, remember that energy efficiency is one of the most important factors for buying one.

Infrared technology is highly energy efficient, environmentally-friendly, and less water-consuming than other heating methods. It is also smaller in size and has unique radiative properties. This makes it an attractive alternative to fossil-fueled heat sources.

Minimal maintenance

It’s critical to maintain your infrared heating elements on a regular basis in order to maximize their efficiency and ensure that they work efficiently and reliably. In addition, proper maintenance can extend the lifespan of your system. While it’s tempting to put off this important process, it’s not a good idea to neglect it.

First, make sure your infrared heater isn’t placed anywhere near flammable or liquid vapors. Also, make sure that you don’t place objects under the reflector, which can block the infrared light from reaching its target. You should also keep the reflector free of dirt or cracks. Finally, make sure that you install the reflector in accordance with the Installation, Operation and Service Manual.

Compared to other heating systems, infrared heating elements do not need any lubrication, motor replacement, or air filters. Rather, they require periodic cleaning of their reflectors and occasional replacement of heating elements. Additionally, they do not produce much noise, so infrared heaters are often used in a quiet setting.

Infrared heating elements are considered “green” alternatives. They produce no CO2 and don’t require any ducting or exhaust, so they’re also considered an excellent choice for open industrial spaces. They can be used to clear walkways in the winter, as well as in loading docks and aircraft hangers. They’re also good for providing comfortable heating in outdoor spaces.