What are the Drawbacks? Do you believe that lighting is a disadvantage in a technological world? The Drawbacks of lighting include but are not limited to the following: Weaker brightness, dimmer lights, increased electrical usage and fire hazards. These things can really be called Drawbacks? Both the yes and no answers are available to these questions.

Industrial Lighting has fewer drawbacks than conventional lighting. Industrial lights have drawbacks but it’s not because they are poor products. Industrial lights have drawbacks due to increased production and reliance on light fixtures for specific jobs within the workplace. Other factors include the ageing of industrial lighting and the prevalence of fluorescent lighting within the workplace. Both of these factors contribute to the drawbacks of industrial lighting.

Industrial lights have many drawbacks, including dimming and marking lights. Lights used to be bright in the past. Nowadays, even some professional commercial and industrial lighting companies still use incandescent bulbs in most of their lighting fixtures. Incandescent bulbs have a great light output (or brightness), but are notoriously expensive and require a lot of electricity to keep their luminosity. Other factors that contribute to the drawbacks of industrial lights are the fire risks and the increased electrical usage.

Aside from the drawback of dimmer lights, do you think that there are any drawbacks to incandescent bulbs? Perhaps the biggest draw Back of them all is that they produce less light than compact fluorescent lamps (CFLs). While CFLs can be as bright and efficient as incandescent lamps, they are also much cheaper and more cost-efficient. In addition to being energy efficient, CFLs are much safer and produce less carbon dioxide than most other types of lights.

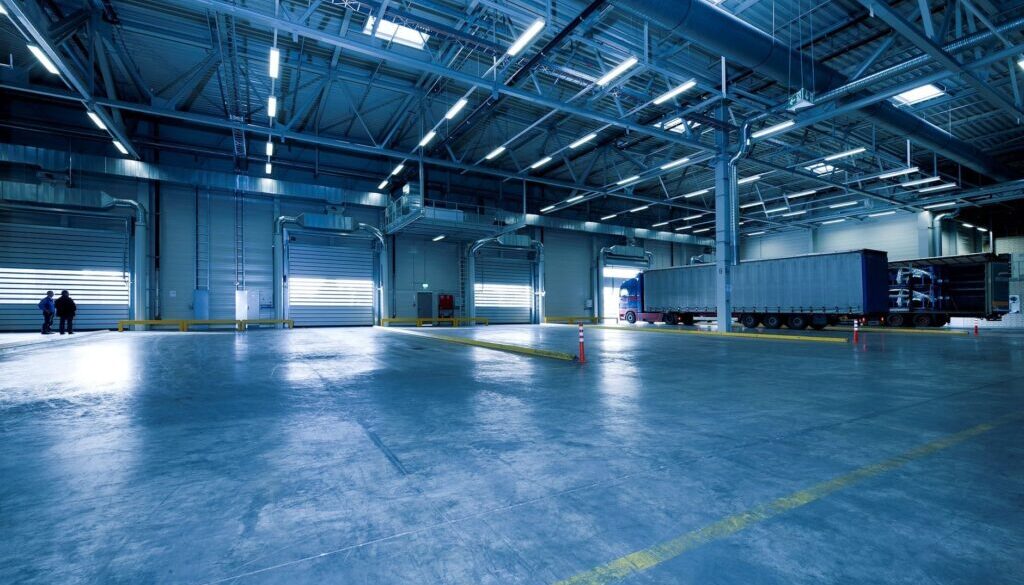

The next draw Back of lights for the industrial or commercial is the fact that most of the commercial lighting is highly concentrated. You will notice that the majority of industrial lighting is concentrated in a few areas. This could be a whole factory floor or even dozens of shelves in a warehouse. In addition to producing vastly more lights for a given area, this type of illumination also consumes a lot of electrical power.

These lights can cause serious damage to workers if they aren’t used correctly. In addition to having to work with dimmer lights that are directed away from their feet, some workers may experience health problems as a result of poor working conditions. The injuries can range from strained muscles to repetitive motion injuries.

You want lights that are bright enough to allow everyone to see if you work in high-visibility environments. Also, industrial lights must be strong enough to resist constant light exposure. Finally, if you are in an industry where there is a requirement for emergency lighting, having a light that is powered by a battery and requires few if any, cords make it easy to access when needed.

You have now been given all the information necessary to answer this question: “Drawbacks of industrial lighting?” It is time to make your decision. These issues can have a significant impact on the daily lives of many, but the benefits outweigh them all. Enjoy all the advantages of lighting up your business and employees. There is no doubt that lighting with present tech is the way to go.